Sourabh Hemant Thakare

Mechanical Engineer

LATEST PROJECTS

BAJA chassis model prototype for Additive Manufacturing using Form 3 SLA printer

-

Modelled a BAJA All-Terrain Vehicle using Autodesk Fusion 360 as modelling ecosystem to be used as a prototype for presentations and business proposals

-

Regulated the geometrical dimensions and tolerances in accordance with the SAE BAJA rulebook

-

Generated, scaled-down, oriented and proper supports were allocated for a successful print using PreForm software by FormLabs

-

Determined the lead time and volume of resin required for printing the model using FormLabs Form 3 printer

FormLabs "OutdoorsIndoor" Design Contest

-

Generation of 3D models for a FormLabs contest based on bringing outdoor activity scaled down to a tabletop adaptation

-

Generated, scaled-down, oriented and allocated proper supports for a successful print using PreForm software by FormLabs

-

Determined the lead time and volume of resin required for printing the model using FormLabs Form 3 printer

Research for Undergraduate tudents projects

-

With an increase in demand for patient-specific implants, additive manufacturing brings cost-effectiveness and increasing complexity to its prime

-

The focus of this research is to determine the biological defect, preparation of CAD design, analysis, optimization and fabrication of a hip implant using AM

-

Got shortlisted for Innovation day contest 2020 at The University of Texas at Arlington

Design Optimization for additive manufacturing of a load-bearing bracket

-

Optimized the existing design with 75% weight reduction in order to reduce build material for costly super-alloys, while retaining similar mechanical and structural integrity

-

Simulated build process and temperature flow after proper allocation of support structure and part orientation for the optimised bracket with process parameters for EOS M290 metal printer

Design for Manufacturing for a Martin Sprocket Screw Conveyor

-

Redesigned a screw conveyor assembly for Martin Sprocket with the objective to reduce manufacturing cost while maintaining or increasing the quality and performance

-

Executed design for manufacturing and design for assembly protocols by enforcing functions including but not restricted to concept design review, preliminary design review and final design review. An elaborated reliability and cost analysis were provided to the manufacturer along with complete CAD assembly and detailed drawings

Additive Manufacturing of Bike Handle Stem on EOS M290

-

Prepared a setup for additive manufacturing of bicycle handle stem by Selective Laser Melting using an EOS M290 Printer with Inconel 718 as the material

-

Allocated multiple iteration of support structures along with part orientations using Atlas3D Sunata as Support generator and Materialize Magics software as an STL editor and finally EOS Print2 for process parameter and build plate setup

-

Reduced total build time and support volume by 20% by changes in part orientation

Reverse Engineering of Neoprene seals for existing Sun Detergent bucket mold design

-

Studied and updated previously used neoprene seals, with the intention to reduce the manufacturing cost and lead timing

-

Prepared newer an updated model in AutoCAD, allocated appropriate geometric dimensioning and tolerancing functions for water jet cutting as the updated manufacturing method instead of stamping thus reducing material wastage and production time

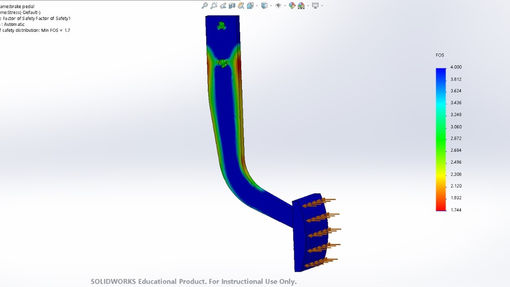

Design and simulation of Braking system for a BMW M3

-

Designed and simulated an entire braking system for BMW M3 which included independent design for both front and rear rotor along with the brake pedal

-

Allocated 75% load on the front ventilated disc and 25% on the rear disc, after a comprehensive literature review

-

Simulated thermal and stress loads for the brake discs and brake pedal, and obtained an optimistic factor of safety value of 8.8 for the front rotor, 13 for the rear and 1.7 for the brake pedal

3D Printing parts for Pneumatic Applications

-

Designed and manufactured a 3D robot interface plate using PolyPrinter 229 and ABS as material for a Staubli RX160 which can withstand high fluctuating air flow from the robot to the ATP F-T sensor

-

Generated a perfect horizontal surface by using a Z-axis probe and conducting trials similar to Coordinate Measuring Machine (CMM)

-

Analyzed and sorted the output data set from the F-T sensor using advanced excel as the analysis tool

Manufacturing Processes and Design of a pulley shaft assembly

-

Designed a model and drawing with appropriate Geometric Dimensioning and Tolerances for a custom build pulley shaft assembly of an industrial band saw

-

Laid out actual manufacturing processes and industrial contacts along with cost estimations for upgraded manufacturing setup with reduced cost and lead timing

BAJA ATV design and manufacturing

-

Designed and fabricated an ATV in accordance to SAE BAJA regulations and competed at MegaATV Championship 2016, Euro Student India 2017, MegaATV Championship 2018, secured pan India 7th rank at MegaATV Championship

-

Successfully played the role of Lead Driver, Steering Head and Manufacturing Lead

Vertical axis wind turbine with a laser grid system for Indian Railway security application

-

Designed and fabricated a vertical axis wind turbine with a singular chord system based off “Quiet Revolution 6” design using aluminium composite as the blade build material

-

Conducted structural analysis on the blades and entire assembly on ANSYS fluent to determine safety and real-life applicability of the turbine

-

Designed a custom-built laser grid system with a buzzer which would get triggered as the lasers would get intercepted thus significantly reducing human and animal casualties

-

Fabricated a 100% functional model with a budget of less than $100

Line Tracer Robot

-

Manufactured a line tracer bot using an Arduino chipset and C++ as the coding language to interpret interruption in the path and activate assigned motor controls to avoid the obstacle

-

Utilized plastic bottles from the trash can to bring environmental awareness at an IEEE level competition and secured 2nd place based on the least time required by the bot to clear the maze